Description

The 20″ x 13″ DoALL 2013-V5 high-speed, vertical contour band saw features variable frequency AC inverter drive controls that start the motion of the band wheels slowly to reduce mechanical shock and increase drive train life, plus a dynamic braking function that rapidly stops motion when power is shut-off. The 2013-V5 upright metal cutting saw is among the most versatile 20″ x 13″ sawing machines on the market today.

20″ New DoAll Vertical Contour Band Saw Model 2013-V5 Specifications:

| Specifications | |

| Capacity | Inches |

| Maximum width | 20″ |

| Maximum height | 13″ |

| Table tilt positive | 10° |

| Table tilt negative | 45° |

| Saw Blade | |

| Band width capacity | 1/8″ – 1″ |

| Band length | 154″ |

| Band Drive | |

| Motor | 5 Hp |

| Band Speed | Low range: 30-320 fpm High range: 550-5,500 fpm |

| Band Tension | Manual |

| Coolant System | |

| Flood | No |

| Mist lubricator | Opt |

| General | |

| Floor Space Dimensions W x L x H | 56″ x 44″ x 80″ |

| Material pass height | 39″ |

| Machine weight | 1,250 lbs |

| Electrical | |

| Voltage requirement (Wye configuration-must specify at order placement) | 208V, 230V, or 460V-60Hz-3ph |

| Total Amp Draw (FLA) | 14.3 (208) 13.7 (230) 9.8 (460) |

20″ New DoAll Vertical Contour Band Saw Model 2013-V5 Features:

- Table tilt to 45 degrees negative-10 degrees positive

- 20″ aluminum band wheels with crowned rubber tires

- Upper wheel adjustment 3″

- Operator controls mounted on column

- One set of high speed, insert type guide blocks for bands 1/8″ to 1/2″

- One set of steel guide inserts for bands 1/4″, 3/8″, 1/2″

- Band wheel brush

- Variable frequency band drive

- Work light

- Manual band tension with indicator

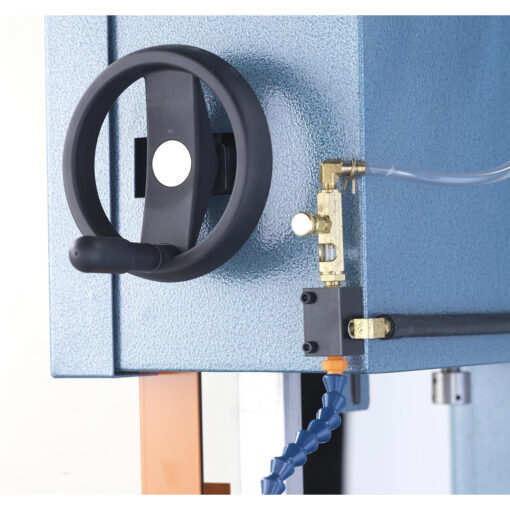

- Post elevating hand wheel

- Chip box

- Chip blower (plant air required)

- Saw blade guards

- Band door interlocks

- Operation and parts manuals on USB stick

- Recommended job selector

- One (1) complimentary DoAll Bi Metal saw blade

- Insert setting gages with wrench and trunnion wrench

20″ New DoAll Vertical Contour Band Saw Model 2013-V5 Optional Accessories:

| CMI-080 12″ Travel glide table with (2) point safety buttons on the handles for blade start | $9,085 |

| CMI-081 18″ Travel glide table with (2) point safety buttons on the handles for blade start | $11,755 |

| 40363 Work holding vise to fit table “T” slots | $1,176 |

| HMD-36 Extended traverse work table: 1100 lb. capacity, four (4) 2″ T-Slots, 34 x 42″ table area, reduces work height by approximately 4″ | $27,611 |

| 299551 DBW-15 welder with grinder, column mounted, for 240 volts and below | $4,119 |

| 299550 DBW-15 welder with grinder, column mounted, for 460 volt | $4,119 |

| Extended work height 6 inch increments-call for quote | Call |

| 5-013007 Work holding jaw with handles | $404 |

| 420288 Band mist lubricator (80 psi plant air required) | $1,860 |

| 47779 Standard rip fence that attaches to 26″ x 26″ table | $1,037 |

| 55305 No. 2 standard cut-off and mitering attachment for 26″ x 26″ table | $1,175 |

| 402080 Disk cutting attachment: capacity 2-1/2″ to 30″ diameter | $2,235 |

| 226028 Magnetic wand chip remover | $195 |

| 80077 High-speed guide blocks for bands 1/8″ to 1/2″, speeds to 6,000 fpm less inserts (per pair) | $418 |

| 80080 Heavy-duty (high-speed) saw guide blocks for bands 1/8″ to 1/2″, speeds to 6,000 fpm less inserts (per pair) | $533 |

| 80079 Heavy-duty (high-speed) saw guide blocks for bands 5/8″ to 3/4″, speeds to 6,000 fpm less inserts (per pair) | $583 |

| 80082 Heavy-duty (high-speed) saw guide blocks for 1″ band, speeds to 6,000 fpm less inserts (per pair) | $910 |

| 80081 Heavy-duty (high-speed) saw guide blocks with carbide-faced backup for bands 1/8″ to 1/2″, speeds to 6,000 fpm less inserts (per pair) | $758 |

| 80085 Heavy-duty (high-speed) saw guide blocks with carbide-faced backup bearings for 5/8″ and 3/4″ bands, speeds to 6,000 fpm less inserts (per pair) | $933 |

| 80162 Heavy-duty (high speed) saw guide blocks with carbide-faced backup bearings for 1″ bands only, speeds to 6,000 fpm less inserts (per pair) | $933 |

| Additional set of hardened tool steel reversible saw guide inserts (set of 4) for any single band width | |

| 80039 1/8″ | $189 |

| 80040 3/16″ | $98 |

| 80041 1/4″ | $98 |

| 80042 3/8″ | $98 |

| 80043 1/2″ | $98 |

| 80044 5/8″ | $98 |

| 80045 3/4″ | $98 |

| 80046 1″ | $98 |

| Optional tungsten-carbide, single-faced saw guide inserts (set of 4) for any single band width | |

| 80100 1/4″ | $583 |

| 80101 3/8″ | $583 |

| 80102 1/2″ | $583 |

| 80103 5/8″ | $583 |

| 80104 3/4″ | $583 |

| 80105 1″ | $583 |

| 80142 Type I high-speed roller guide blocks, less rollers (per pair) | $1,158 |

| Set of rollers for band saw width (must purchase 80142) | |

| 80089 1/4″ | $1,788 |

| 80092 3/8″ | $1,788 |

| 80093 1/2″ | $1,788 |

| 80094 Type II high-speed roller saw guide blocks, less rollers (per pair) reduces work height 1″ and restricts table tilt to 27″ | $1,788 |

| Set of Type II rollers for band saw width (must purchase 80094) | |

| 80095 1/4″ | $2,163 |

| 80096 3/8″ | $2,163 |

| 80097 1/2″ | $2,163 |

| 80098 5/8″ | $2,163 |

| 80099 3/4″ | $2,163 |

| 80047 1″ | $2,163 |

| 299998 Additional USB stick of manuals | $92 |

| NRTL A Nationally Recognized Testing Laboratory (NRTL) is an independent third-part laboratory recognized by the United States Occupational Safety and Health Administration (OSHA) to test and certify products to applicable product safety standards | $3,500 |

| SVC CHARGE LABOR Five (5) hours installation and operator training | $750 |

| Warranty DoALL Cut Above 10 Year Warranty Annual Investment | $840 |

| 1200025 Starter Kit of Six Pack Blades Consist of 3 each Silencer GP 5-8, and 1 of each Silencer GP 6, 6-10, 8-12 | $310 |

| 21200045 5 Gal. Pail of AL-2000 Mist Coolant | $240 |

| 24000001 Tool-Saver lubricant stick | $14 |

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/

All product information including but not limited to price, specifications, color, photos, equipped with and features are subject to change.

Reviews

There are no reviews yet.