Description

| Shear for Profiles | |

| Flatbar with slight deformation | 30″ x 3/4″ |

| Length of blade | 30-1/8″ |

| Square bar | – |

| Work height | 34-1/4″ |

| C Shears for Profiles | |

| Shearing power | 300 ton |

| L at 90º shear without deformation | 8″x 8″ x 3/4″ |

| L at 45º | 2 3/4″x2 3/4″x1/4 |

| With Special Blade | |

| L at 90º (shear with slight deformation) |

8″x8″x1″ |

| Shears for Solid Bars | |

| Round bar ø | 2-3/8″ |

| Square bar | 2-3/8″ |

| With Special Blades | |

| UPN Profiles | 7″ |

| IPN Profiles | 7″ |

| Notching | |

| Plate thickness | 5/8″ |

| L of | 4-3/4″ |

| Depth | 4-3/8″ |

| Width | 2-1/4″ |

| Punching | |

| Punching Power | 240 ton |

| Maximum capacity with quick change | |

| and die with gooseneck die holder | ø 1-1/2″x1-1/2″ |

| Throat depth | 18-3/4″ |

| Stroke | 4″ |

| Work height | 43-3/4″ |

| General Specifications | |

| Punch stroke per minute (based on 3/4″ travel) |

26 |

| Motor | 20 h.p. |

| Approx. net weight with production pack | 15,435 lbs |

| Gross weight | 17,750 lbs |

| Packaging dimensions | 119-3/4″ x 63″ x 94-1/2″ |

245 Ton New Geka Ironworker Dual Cylinder Model Hydracrop 220/300 SD Features:

Two hydraulic cylinders ironworker with two simultaneous work stations and five work stations.

- Punching (240Tn power)

- Notching

- Shear of flatbars (300 Tn power)

- Shear of iron section L at 90º

- Cut of round and square bars

Hyd 220 is suitable for punching and shearing base plates for metallic constructions.

2 VERSIONS ON EACH MODEL: S, SD

“S” VERSION

- Machines driven by two cylinders.

- 5 work stations, fitted with tools for L, shearing, round and square bars, rectangular notching and punching

- Quick change punch

- Flat bar shearing table with adjustable guides

- 2 simultaneous work stations

- Greater speed backed by a powerful hydraulic unit.

- Special equipment for approaching at reduced pressure and slow speed.

- Precision punching table with X & Y measuring stops.

- Precision notching table with X & Y measuring stops

- Ready for production pack comprising:

- One meter “touch & cut” length stop with fine adjusting.

- Lamp for enhanced vision of cutting zones.

- 10 sets of round punches and dies.

“SD” VERSION

- The same features as the S version, but with a deeper throat for larger plate and sheet metal applications.

Working Stations:

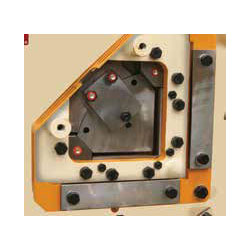

Notching Station:

This station of the machine has been designed to mount several optional accessories, all of which are normally held in stock.

- Triangular notching at 90º.

- Punching equipment.

- Pipe notching equipment.

- Radiusing of flat bar ends.

- Radiusing corners.

- Notching of footings, etc. ng corners.

- Rectangular Punch

- Rectangular Stripper

- Rectangular notching lower blades

- Table with scaled measuring stops, included in Production Kit

- Cross centring Frame bolts

- Tapped holes for special tooling

Shearing of flat bar:

The excellent stability of the monoblock bladeholder, which is controlled at the each end, makes it possible to mount a long upper blade with a proven geometry to obtain optimum shearing quality. The radial system allows a generous cutting capacity as a result of the force multiplier effect.

- Upper blade with special geometry.

- Lower blade.

- Supplement shearing angle control of upperblade, for shearing without deformation.

- Guide fixing screw.

- Clearance control of blade-holder.

- Adjustable guides 45º right and left.

- Clearance control between shear blades.

- Flat plate/bar shearing table.

- Slotted guide positioning with coverage of the entire blade length.

L cutting angle:

Fully aware of the importance of distortion free shearing, GEKA has designed a patented system of a floating upper blade that travels along a rectilinear line and is able to shear angles without

any deformation or loss of material (single cut); All GEKA Hydracrop models ensure the distortion problem caused by the conventional radial system is now a problem of the past.

- Safety protection.

- Upper shear blade guides.

- Lower shear blade guides.

- Upper shear blade without deformation.

- Blade gap adjustment screws.

- Adjustable Support.

Cutting of B and A bars:

The GEKA HYDRACROP machines are fitted as standard with blades for cutting B and A bars. Furthermore, this station has been designed bearing in mind the shearing of other sections such as D, E , T for which a large stock of blades is available.

- Adjusting bolt and height setting of the guide.

- Blade holding flanges.

- Guide fixing bolts.

Punching station:

Fitted with an independent cylinder creating a large, flexible, universal workstation easily adaptable for mounting special tools and “die sets”.

- Cylinder support

- Split double acting cylinder.

- Limit switches for punch travel setting.

- Generous travel for bending, deep-drawing, forming jobs etc

- Adjustable generous non-turning guiding.

- Additional guiding for damping of offset forces and protection of hydraulic seals.

- Quick punch change.

- Adjustable material stripper.

- Table with millimetre scales, included in production kit.

- Adjustable measuring stop.

- Gooseneck die-holder for punching channel and section.

- Adjustable bolster locking device X axis.

- Adjustable bolster locking device Y axis.

- Fixing bolt at base of gooseneck.

Electric cabinet:

Manual selector switch / electrical limit switch. ”Inching / Jogging” selector switch. Easily removable cover to access hydraulic unit.

245 Ton New Geka Dual Cylinder Ironworker Model Hydracrop 220/300 SD Accessories:

| Standard Punching Attachment Complete | $2,834.00 |

| Standard Gauge Table Complete SD | $1,469.00 |

| 3.94″ Oversize Complete | $4,694.00 |

| 3.94″ Oversize Gauge Table Complete SD | $1,365.00 |

| Fixed 3.94″ Oversize Gauge Table SD | $1,032.00 |

| 6.29″ Oversize Attachment | $5,170.00 |

| 6.29″ Oversize Gauge Table Complete SD | $1,469.00 |

| Fixed 6.29″ Oversize Gauge Table SD | $1,032.00 |

| X Laser | P. O. R. |

| Multi Stop Table SD Only | $5,808.00 |

| Urethane Punching Hold Down | P. O. R. |

| Additional Retractable Stop for Multi Stop | $449.00 |

| Left to Right Press Brake Attachment | $2,904.00 |

| Front to Back Press Brake Attachment SD | $3,754.00 |

| Base Flip Stop Unit SD Models | $3,971.00 |

| 80″ Extension to Flip Stop | $2,328.00 |

| Additional Flip Stop Complete | $128.00 |

| Rectangle Notcher Complete | $1,678.00 |

| Rectangle Notcher Gauge Table | $1,655.00 |

| V Notcher Attachment Complete | $2,579.00 |

| V Notcher Gauge Table | $1,655.00 |

| Pipe Notcher Attachment with 1 Set of Tooling | $2,015.00 |

| Pipe Notcher Die | $232.00 |

| Pipe Notcher Punch | $255.00 |

| Punch on Notcher | $2927.00 |

| Press Brake on Notcher | $2,664.00 |

| Set of U Shearing Blades | $1,802.00 |

| Set of T Shearing Blades | $1,802.00 |

| Set of I Shearing Blades | $1,802.00 |

| Set of Special Shearing Blades Multiple Round & Square | $2,200.00 |

| Set of Special Shearing Profiles | $2,440.00 |

| 40″ Length Gauge Complete | $1,361.00 |

| Extension to Length Gauge in 40″ Sections | $352.00 |

| Manual LUPPS Attachment | $1,975.00 |

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/