Description

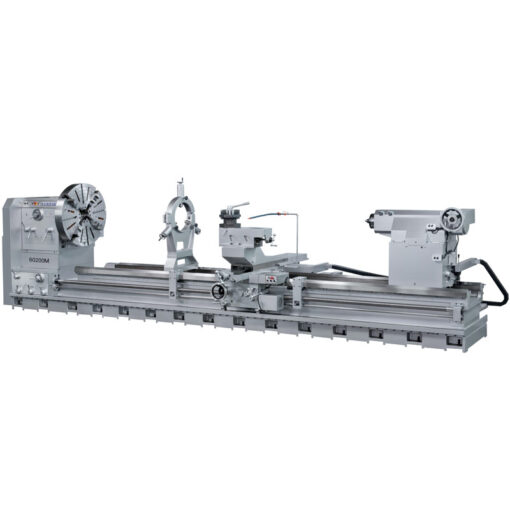

The big bore lathe is ideal for large pipe works in oil fields and big valves works. This series offers spindle bores up to 15″, center distance range from 60″ to 315″. The machine bed is 32″ wide. Double chucks are available for holding extra long and large work pieces.

38″ x 200″ New Sharp Heavy Duty Big Bore Lathe Model 38200M-32 Specifications:

| CAPACITY | |

| Swing Over Bed | 37.8″ |

| Swing Over Cross Slide | 21.65″ |

| Swing Over Gap | 48.82″ |

| Distance Between Centers | 196.9″ |

| HEADSTOCK | |

| Spindle Speed | 4-420 rpm |

| No. of Spindle Speeds | 16 steps |

| Spindle Nose | A2-11 |

| Spindle Bore | 6″ |

| THREADS AND FEEDS | |

| Inch Threads, Number | 0.25-30 tpi, 70 |

| Metric Threads, Number | 1-120 mm, 62 |

| Modular Threads, Number | 0.25-30 MP, 53 |

| Diametral Pitch Threads, Number | 1-120 DP, 70 |

| Longitudinal Rapid Feeds | 82.68 IPM |

| Cross Rapid Feeds | 41.34 IPM |

| Leadscrew Pitch, Diameter | 2 tpi, 2.36″ |

| CARRIAGE | |

| Cross Slide Travel | 23.62″ |

| Compound Travel | 15.75″ |

| Compound Width | 34.65″ |

|

Max. Size Cutting Size

|

1.26″ x 1.26″ |

| BED | |

| Bed Length | 273.6″ |

| Bed Width | 31.9″ |

| Width of Gap (without chuck) | 21.26 |

| TAILSTOCK | |

| Quill Diameter | 7.87″ |

| Quill Travel | 11.8″ |

| Quill Taper | MT #6 |

| Body movement | Electrical , 0.5 H.P. |

| Quill movement | Manual |

| GENERAL | |

| Spindle Motor | 30 HP |

| Voltage | 220V/440V |

| Phase | 3 phase |

| Approximate Weight | 28,820 lbs |

| Dimensions | 301.2″ x 85.5″ x 59.5″ |

38″ x 200″ New Sharp Heavy Duty Big Bore Lathe Model 38200M-32 Features:

-

Casting: One piece casting work with reinforced inner structure, extra 3rd support to be suitable for processing of large work piece and enhanced heavy-duty cutting ability. The removable gap has built in reinforced structure and does not affect any cutting stability.

-

Spindle:

-

1. Bore 6 “, 16-step speed change, turbine speed change mechanism with no easy speed jumping and three point support for the box.

-

2. Fitted with adjustable, electromagnetic brake for easy braking adjustment according to different work piece materials and speed.

-

3. Gear and shaft are made of super alloy material with FAG bearings to offer durable cutting and low production noise.

-

4. Sealed oil bath lubrication system with enforced oil supply by mechanical pump to achieve better lubrication effects.

-

-

Gear Box: Metric / Inch gear box free from gear exchange to improve production efficiency. Speedy installation, forward and reverse movement, safety installation with automatic sealed oil bath lubrication system.

-

Apron Feeding Device: Swift transmission, positive and negative rotation movement and safety device with auto sealed oil bath lubrication & cross rapid feeding.

-

Saddle: Anti-friction processed surface with regular oil injection, lubricated and friction endurable.

-

Tailstock: Two stage in-feed device, swing arm movement to have smooth and labor saving operation.

-

Electrical Control: 2 stage safety start-up device and overloading power cut system.

-

Castings: FC-30 steel is used for main structures like base, spindle, saddle and tailstock, which are annealed and have no deformation.

-

Processing: Base, spindle, saddle, slot surface of traveling plate, tool base sliding table, tail shaft pipe are high frequency treated, precision ground for extended service life.

-

Headstock Gear and shaft are made of super alloy material with FAG bearings to offer durable cutting and low production noise, Turbine speed change mechanism with an easy speed jump. Three point support for the box.

- Electric box 2 stage safety start-up device, durable cutting and low production noise. Overloading power cut System, Filtered with adjustable , electromagnetic brake for easy braking adjustment according To different work piece materials and speed.

- Lubricating Device for Headstock

- Spindle Motor : 30 HP

- Electromagnetic Brake

- Metric / Inch Gear Box

- Change Gear

- Longitudinal & Cross Rapid Feeding

- Tailstock Two Steps Device

38″ x 200″ New Sharp Heavy Duty Big Bore Lathe Model 38200M-32 Standard Equipment:

- Coolant Device

- X, Z – axes Auto Lubrication System

- X, Z – axes with Turcite-B

- Coolant system

- Steady Rest 16”, Bearing Type (grip range 60-400 mm)

- Face Plate with 4-Jaw 40”

- Dead Center

- Center Sleeve MT#6

- Toolpost Screw Wrench

- Level Pads

- Tools and Tool Box

- Operation Manual

- Lubricating Device for Headstock

- Spindle Motor : 30 HP

- Electro-Magnetic Brake

- Metric / Inch Gear Box

- Change Gear

- Longitudinal & Cross Rapid Feeding

- Tailstock Two Steps Device

38″ x 200″ New Sharp Heavy Duty Big Bore Lathe Model 38200M-32 Optional Accessories:

| Rear chuck adapter for 6” bore with chuck cover up to 32” | $2625.00 |

| Chuck guard up to 32” with limit switch | $665.00 |

| 3-jaw strong scroll chuck SK-16”( 6” bore) with A2-11 back plate | $8060.00 |

| 3-jaw strong scroll chuck SK-20”( 8” bore) with A2-11 back plate, clamping range OD: 25-480 mm, ID: 125- 460mm | $10,735.00 |

| 3-jaw strong scroll chuck SK-24.8”( 7” bore) with A2-11 back plate | $17,260.00 |

| 4-jaw independent chuck A2-11-20” ( 6” bore) grip range ID: 55-555mm, OD: 175-575mm | $3790.00 |

| 4-jaw independent chuck A2-11-24” ( 6” bore) grip range ID: 75-450mm, OD: 170- 475mm | $6585.00 |

| 4-jaw independent chuck A2-11-26” ( 6” bore) grip range ID: 55-605mm, OD: 175-625mm | $9015.00 |

| 4-jaw independent chuck A2-11-32” ( 6” bore) grip range ID: 55-960mm, OD: 205-975mm | $17,440.00 |

| 4-jaw independent chuck A2-11-40” ( 6” bore) grip range ID: 55-960mm, OD: 205-975mm | $24,575.00 |

| Follow Rest, 60 mm to 280 mm | $2,940.00 |

| Steady Rest w/ Bearing 16” | $6,470.00 |

| Steady Rest w/ Bearing 24” | $7,330.00 |

| Back splash | $5,030.00 |

| Roller Support ( mount on bedway) | $7,040.00 |

| Roller Support for Chuck | $8,195.00 |

| Taper Attachment( 450 mm travel, +/- 8 degrees) | $10,420.00 |

| 4-Way Rapids ( power) on the top slide | $9,625,00 |

| 6-Way Rapids ( power) on the top slide | $12,045.00 |

| Live Center, MT# 6 | $2,035.00 |

| 40 HP in lieu of 30 HP | $3,180.00 |

| 50 HP in lieu of 30 HP | $4,210.00 |

| Digital Readout and installation | Call for price |

| UL components upgrade | $3,355.00 |

| UL certificate for State of California | Call for price |

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/