Description

78.4″ x 98.4″ New OM CNC Vertical Boring Mill Model NEO Alpha-20EX Specifications:

| MACHINE CAPACITY | ||

| Table diameter | ø 78.74″ | ø 2,000 mm |

| Maximum turning diameter | ø 98.4″ | ø 2,500 mm |

| Maximum swing | ø 98.4″ | ø 2,500 mm |

| Maximum cutting height | 78.74″ | 2,000 mm |

| Maximum load on table | 33,070 lbs | 15,000 kgs |

| Maximum height from table top to gauge line | 86.22″ | 2,190 mm |

| Maximum torque of table | 19,910 ft. lbs | 27,000 Nm |

| Maximum cutting force | 5,620 lbs | 25,000 N |

| Maximum drill diameter | ø 3.15″ | ø 80 mm |

| (Tool: Cemented carbide, Work: S45C) | ||

| Maximum tap diameter | M42 x 4.5 | |

| (Tool: HSS, Work: S45C) | ||

| CROSSRAIL | ||

| Elevating travel of crossrail | 47.24″ | 1,200 mm |

| Crossrail positioning step | 7.87″ 7 step | 200 mm 5 step |

| TOOL HEAD | ||

| Horizontal travel (X-axis) | ||

| To right from table center | 69.29″ | 1,760 mm |

| To left from table center | 3.93″ | 100 mm |

| Vertical travel (Z-axis) | 43.31″ | 1,100 mm |

| Ram size | 8.27″ x 8.27″ | 210 x 210 mm |

| Minimum hole diameter allowing passage of ram | ø11.81″ | ø 300 mm |

| Turning tool shank size | 1.26″ x 1.26″ | 32 x 32 mm |

| Taper of milling spindle nose |

JIS B6340 No. 50 (BIG-PLUS)

|

|

| SPEED |

|

|

| No. of table speeds 2 x infinitely variable |

|

|

| Table speed range |

|

|

|

Low 1.0 ~ 61.0 min-1

|

||

|

High 3.8 ~ 230 min-1

|

||

|

Inching 2min-1

|

||

| Rapid traverse (X-axis) |

393.70 inch/min

|

10,000mm/min |

| Rapid traverse (Z-axis) |

393.70 inch/min

|

10,000mm/min |

| Manual feed rate (X, Z axes) |

0~141.73 inch/min

|

0~3,600mm/min |

| Cutting feed per rev. |

0.0004~20″

|

0.01~500 mm |

| Cutting feed rate |

0.04~141.73″

|

1.0~3,600mm/min |

| Elevating speed of crossrail |

11.81 inch/min

|

50Hz: 300mm/min |

|

14.17 inch/min

|

60Hz: 360mm/min | |

| Milling spindle speed |

25~2,500 min-1

|

|

| Table indexing speed (C-axis) |

3 min-1

|

|

| Manual feed rate (C-axis) |

0~800 deg/min

|

|

| MOTORS |

|

|

| Drive motors for turning (continuous/30min) |

60/75 HP

|

45/56 kW |

| Milling spindle motor (continuous/30min) |

20/25 HP

|

15/18.5 kW |

| Axis feed motor |

|

|

|

X-axis: AC servo

|

2.5 HP 1.8 kW | |

|

Z-axis: AC servo (with brake)

|

9 HP 7.0 kW | |

|

ATC magazine motor

|

1 HP 0.75 kW | |

|

Crossrail elevating motor

|

7 HP x 4P 5.5 kW x 4P | |

|

|

Others 4 HP total 3.0 kW | |

| ATC DEVICE |

|

|

|

Tool selection system Fixed – address, shortest path random No. of tools stored 24 pieces

|

||

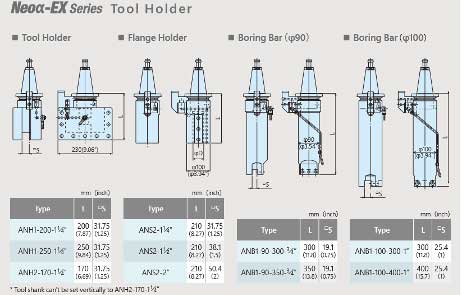

| Maximum length of tool holder (from mounting face) | 16.14″ 410 mm | |

| Maximum weight of tool holder (with holder base) | 110 lbs/piece 50 kg/1pce | |

| Maximum protrusion of tool stored in magazine (from ram center to tool end) | ID side 6.89″ 175 mm | |

| OD side 6.89″ 175 mm | ||

| Maximum length of milling tool (from gauge line) | 16.14″ 410 mm | |

| Maximum distance of milling tool (at 2.44″ (62mm) or more from gauge line) | ||

| In case of other tools adjoining | 5.91″ 150 mm | |

| In case of no tools adjoining | 9.84″ 250 mm | |

| Maximum weight of milling tool | 55 lbs/pc 25 kg/pc | |

| Milling tool taper shank | BT50 | |

| Shape of pull stud P50T-2 | (MAS 403) | |

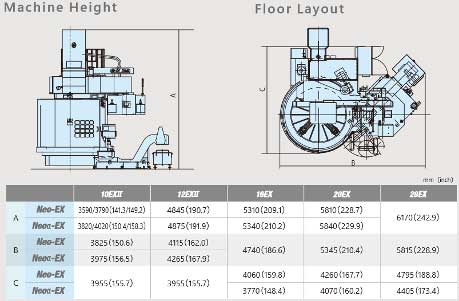

| MACHINE SIZE | ||

| Machine weight | 49,610 lbs | 22,500 kgs |

| ACCURACY | Static and machining accuracy | Japan Industrial Standards |

| Circularity | 0.0006″ | 0.015 mm |

| Cylindricity | 0.0008″ for 20″ 0.02 mm for 500 mm | |

| 0.0012″ for 40″ 0.03mm for 1000mm | ||

| Flatness | 0.0012″ for ø40″ 0.03mm for ø 1000 mm | (Crown is not permitted) |

| N.C. ACCURACY TEST | ||

| Positioning | X-axis ±0.0003″ for 20″ | ±0.007mm for 500 mm |

| Z-axis ±0.0003″ for 20″ | ±0.007mm for 500 mm | |

| C-axis ±10 seconds | (unidirectional positioning) | |

|

Repeatability of linear axis

|

X-axis ±0.0002″ | ±0.005 mm |

|

|

Z-axis ±0.0002″ | ±0.005 mm |

|

|

C-axis ±5 seconds | |

| POWER SOURCES | ||

| Electric power supply | 220 V±10%, 60 Hz, 3 phase | |

| Operating voltage | AC 100V, DC 24V | |

| Power capacity | 100 kVA |

78.4″ x 98.4″ New OM CNC Vertical Boring Mill Model NEO Alpha-20EX Features:

- FANUC 0i-TD CNC Controller

- Independent 4-jaw chuck table

- Twenty-four (24) tool automatic tool changer

- Six (6) standard tool holder package

- Chip cover (manual open and shut)

- Maintenance tools kit

- Foundation parts kit (Includes foundation plates, leveling blocks, and anchor bolts)

- Work light

- Signal tower light (3-steps LED type)

- Yellow: when the machine is put in a stationary condition on automatic operation. (M00, M01, M02, or M30 and end of single block)

- Green: During automatic operation

- Red: Alarm

- Electric spare parts

- Crossrail traveling

- X-axis telescopic cover

- Center through coolant

- PSI Indication

- X-axis scale feedback

- Standard hinge belt chip conveyor

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/