Description

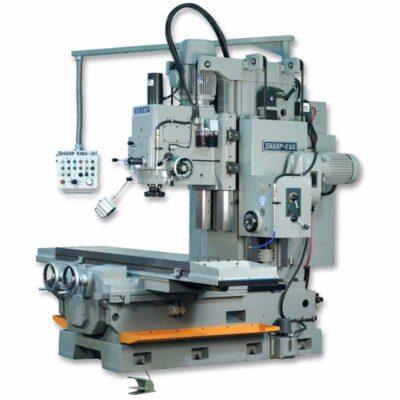

9″ x 49″ New Bridgeport Mill Series 1 Standard Package 4

The New Bridgeport Mill Standard Package 4 is configured with the following. Inch Screws and Dials, (Special Order Only Erickson #30 Quick Change Spindle), Chrome Ways and Gibs, One-Shot Lube, No Power Feed. 230V 60Hz, 208V 60Hz or 460V 60Hz.

NOTE: THESE ARE SPECIAL ORDER BRIDGEPORTS – If you are looking for the STANDARD new Bridgeport mill for sale standard package 1 click here.

Built the Bridgeport Way

The long-term reliability of a Series I mill is the result of its design features, the quality of its components, and the craftsmanship of its hand-scraped ways and precision ground fits. Every Hardinge-Bridgeport knee mill is built to last as if you would build it for yourself. That’s why the resale value of a Bridgeport mill remains consistently high. The “bargain” imitators can’t say that. Our competitive prices are a result of our higher volumenot from building a cheaper machine. Rigidity starts with the main frame components of a machine, and for this reason, the strength and damping qualities of gray cast iron was chosen.

Patented 2J head

The unique and patented air cooling system of the “2j” head ensures that any heat buildup in the spindle bearings, belt or quill area is kept to an absolute minimum. This is achieved by air being drawn into the belt housing and past the spindle bearings by the rotation of the drive belt It is then exhausted out of the head assembly at the top of the casting.

Distortion and inaccuracy due to excessive heat rise is kept to a

minimum by maintaining the operating temperature within 20 degrees

fahrenheit of ambient temperature. This also results in increased belt and bearing life, as well as more consistent accuracy. Also, with no external cooling fans, vibration is reduced and the ongoing maintenance or threat

of a fan failure is eliminated. Fans also frequently require a step-down transformer if the machine is wired for power greater than 110 Volts.

Series I One-shot lubrication

Adequate lubrication ensures a long accurate life for the machine. It also reduces maintenance and makes the machine more sensitive and easier for the operator to use. A metered, centralized system lubricates all of the ways and screw assemblies of the machine. Operation of the system by a single lever saves the operator time and makes it easy to always provide the correct amount of oil, predetermined by a series of metering valves built into the system. Many competitive systems do not meter lubrication, which allows the oil to flow to the point of least resistance.Thus one sliding member may receive more oil than another; possibly causing excessive wear to the area that is not getting properly lubricated. An optional Automatic Lubrication System is also

available.

Hand-scraped ways

All alignment ways and gibs are completely hand scraped to within tenths of a thousandth.This ensures optimum machine geometry, rigidity and accuracy.

9″ x 49″ New Bridgeport Mill Series 1 Standard Package 4 Specifications

| Table Size | 9″ x 49″ |

|---|---|

| Table travel (X-Axis) | 36″ (914 mm) with Power Feed |

| Table travel (X-Axis) | 31″ (787 mm) without Power Feed |

| Saddle Travel (Y-Axis) | 12″ (305 mm) |

| Quill Travel | 5″ (127 mm) |

| Knee Travel (Z-Axis) | 16″ (406 mm) |

| Ram Travel | 12″ (305 mm) |

| Throat Distance (Min.) | 6.75″ (171 mm) |

| Throat Distance (Max.) | 18.75″ (476 mm) |

| Spindle (2J Head) | |

| Power Rating 30 min. Duty Cycle | 3 HP (2.2 kW) |

| Power Rating Continuous | 2 HP (1.5 kW) |

| Tooling | R-8 Collets |

| Drilling Capacity | |

| Power Quill Feed 3 | 3/8″ (9.5 mm) |

| Manual Drilling Capacity | 2 CI/min |

| Boring Range | 6″ dia. (152 mm) |

| Spindle Diameter | 1.875″ (48 mm) |

| Quill Diameter | 3.375″ (86 mm) |

| Speed Range | |

| High (Infinitely Variable) | 500 – 4,200 RPM @ 60 Hz |

| Low | 60 – 500 RPM @ 60 Hz |

| Power Quill Feed | 0.0015″/rev (0.038 mm) |

| Manual Adjust | 0.003″/rev (0.076 mm) |

| Manual Adjust | 0.006″/rev (0.152 mm) |

| Worktable | |

| Standard | 49″ x 9″ (1,245 x 299 mm) |

| T Slot center distance | 3 @ 2.5″ (64 mm) |

| T-Slot Size | 0.625″ (16 mm) |

| Height Above Floor (Max.) | 47.25″ (1,200 mm) |

| Weight of Workpiece (Max.) | 750 lb (340 kg) |

| Machine Size | |

| Height | 87″ (2.21 m) |

| Weight | 1,930 lb (875 kg) |

| Weight (Shipping) | 2,075 lb (941 kg) |

| Floor Space | 7′ x 10′ (2.13 x 3.0mm) |

| #BPKMQCSTD |

9″ x 49″ New Bridgeport Mill Series 1 Standard Package 4 Features

- Chrome Plated Ways

- One Shot Lube

- Variable Speed Drive

- Back Gear For Heavy Milling

- Draw Bar

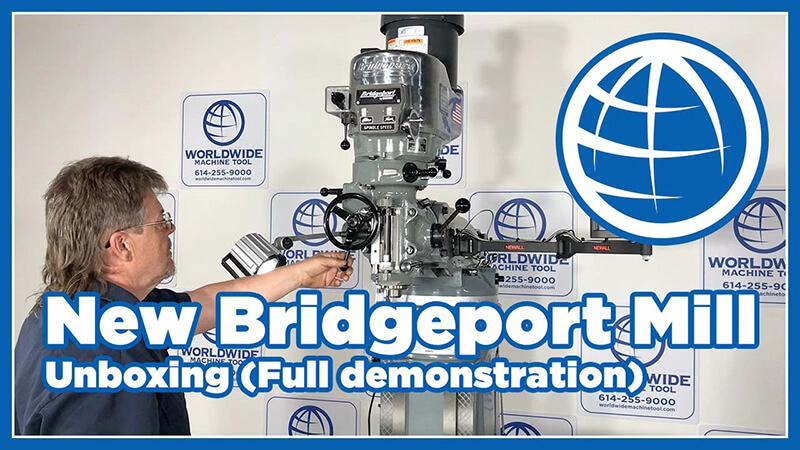

New Bridgeport Mill unboxing video (Full demonstration)

Customize your new Bridgeport knee mill for sale with these optional accessories.

| Digital Readouts | |

| Newall : X and Y – Installed | $3,075 |

| Newall : X, Y, and Z – Installed | $4,010 |

| Acu-Rite : X and Y – Installed | $3,299 |

| Acu-Rite : X,Y, and Z – Installed | $4,211 |

| Power Feeds | |

| Servo : X Axis Power Feed – Installed | $1,300 |

| Servo : Y Axis Power Feed – Installed | $1,300 |

| Servo : Z Axis Power Feed – Installed | $1,300 |

| Align : X Axis Power Feed – Installed | $950 |

| Align : Y Axis Power Feed – Installed | $950 |

| Align : Z Axis Power Feed – Installed | $950 |

| Accessories | |

| 6” Kurt Vise | $705 |

| Swivel Base for Machine Vise | $460 |

| Work Light | $433 |

| R-8 Collet Tray – Installed | $259 |

| Power Drawbar for R-8 Spindle | $1,725 |

| Power Drawbar for R-8 Spindle with NFPA electrics | $1,725 |

| Accu Lube Advantage Applicator | $1,550 |

| R-8 Collets Set – 11 collets, 1/8” to ¾” (in 1/16” increments) | $540 |

| R-8 Collets Set – 12 collets 1/16” to ¾” (in 1/16” increments) | $583 |

| #3-2J Right-angle attachment (accommodates R-8 collets) | $2,180 |

| Vise Step Key Kit | $41 |

| Work Light (Twist-Loc Plug, used with NFPA Electrics) | $433 |

| NFPA Electrics (208-24-460V, 60 Hz) – Installed | $9,970 |

| Operation and Maintenance Manuals | $61 |

| Export Only Crating | $555 |

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/