Description

25 Amp New CHMER G32S Wire EDM is the product of decades of experience building EDM machine tools. It is a three-piece design, comprised of the machine tool, DI tank, and CNC control.

The name CHMER (“shim-mer”) sounds funny, but CHMER is a very serious player in the EDM world. They have been in business for over 40 years building EDMs and their high-speed mills. CHMER has five manufacturing facilities and includes their 24,000 sq. meter manufacturing facility in Taichung, Taiwan. Like EDM Network, CHMER’s philosophy is to do what they do best. They build their own power supplies and CNC controls, right down to the PC board-level. They build the machine tools and use only high-quality components on them, such as Intel PC, Panasonic AC Servo Motors, and Servo Packs, Heidenhain and Fagor Glass Scales and Grundfos pumps, etc. The R&D facility is constantly ensuring that CHMER is at the forefront of EDM technology. CHMER is ISO 9000 and ISO 14000 certified. They also write all their own software. They are a totally independent manufacturin company.

25 Amp New CHMER G32S Wire EDM Specifications:

| Travels X | 14.1″ (360mm) |

| Y | 9.87″ (250mm) |

| Z | 8.6″ (220mm) (7.9″ submerged (200mm)) |

| U | 2.4″ (60mm) |

| V | 2.4″ (60mm) |

| Maximum workpiece dimensions | 29.3 x 22 x 8.5” (725 x 560 x 215mm) |

| Maximum workpiece weight | 660 lbs (300kg) |

| Drive system | Direct drive AC motors on all five axes |

| Minimum resolution | 0.00004” (.001mm) |

| Wire diameter range | .006~.012 (.004 optional) (.15 – 3.0mm) |

| Rated cutting speed | 24 sq in/hr (2″ thick, .010” Megacut D) |

| Maximum taper angle | 14.50at 3.25“thick, ± 45º w/Special Guides |

| Outside dimensions including DI and CNC | 90.5 x 90.5 x 83″ (2,300 x 2,300 x 2,100mm) |

| Weight | 5,225 lbs. (2,375 kg) |

| Dielectric System | |

| Capacity | 90 gallons (590 Liters) |

| Filter elements | Paper |

| Conductivity control | digital, automatic |

| Water temperature control | chiller, automatic |

| CNC Control | |

| Best surface finish | Better than Ra 0.5µm (.25 w/optional ACU Fine Finish) |

| Circuit system | Power MOS Transistor |

| Maximum current output | 25 Amp |

| Data input | MDI, LAN port, RS-232, and USB Port |

| Display | 15” color TFT. |

| Controllable axes | 6 (6th axis must be purchased separately) |

| Cutting conditions | 10,000 |

| Input power | 220~230 VAC, 60 Hz, 13KvA |

Specifications are subject to change without prior notice

25 Amp New CHMER G32S Wire EDM Main Features:

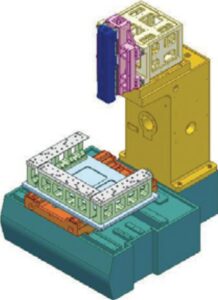

25 Amp New CHMER G32S Wire EDM is the product of decades of experience building EDM machine tools. It is a three-piece design, comprised of the machine tool, DI tank, and CNC control.

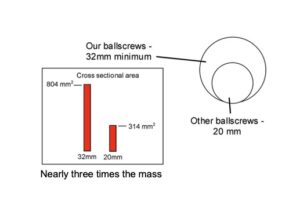

- Ultra-high precision ball screws and LM Guides (ways)

- Double-anchored, oversized ball screws: 32mm X & Y, 20mm U & V

- Truss type U V Axis design

- Direct drive Panasonic AC motors on all five axes

- Submerged cutting

- The fastest & most reliable Auto Threader in the business

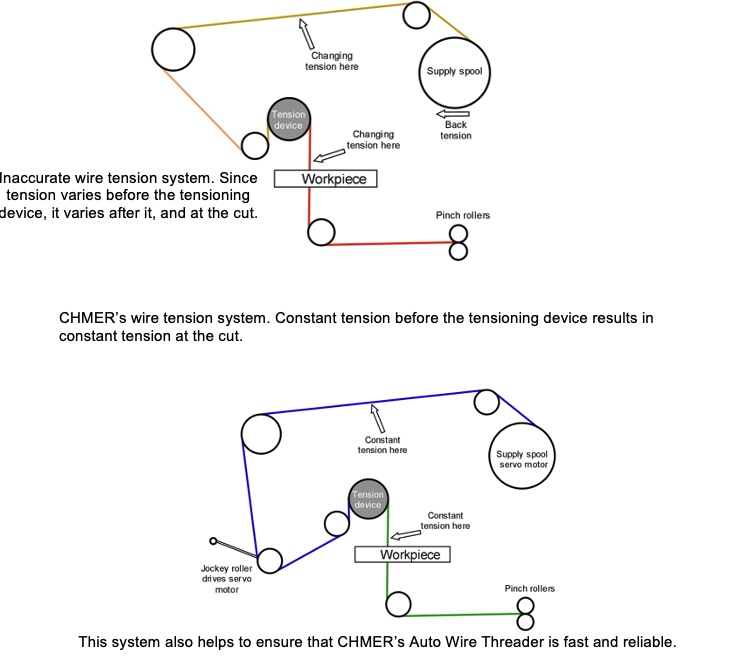

- Jockey Roller wire feed system – no back tension or brake to adjust on supply spool-eliminates jerking and provides very precise wire tension.

- Solid round wire guides not split guides.

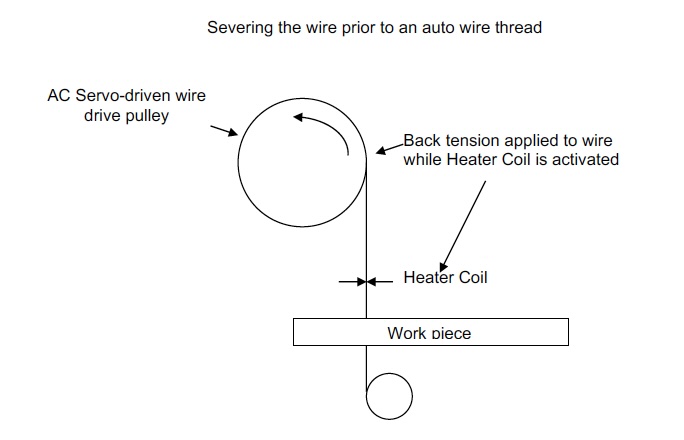

- AC Servo-driven Auto Wire Threader and wire tensioning – not a powder brake or clutch

- LCD Remote control- jog, center and edge find, AWT, position display, etc.

- Self-cleaning and self-lubricating tank seals reduce maintenance time and enhances accuracy.

- Stainless Steel Tank

- Auto lube system

- Auto fluid level control – water level is determined by the position of the upper head.

- Tank door interlock switch – will not fill tank with door open.

- Digitally controlled DI system

- Work light

- Chiller

- Wire Tip Disposal

Construction

Construction

The casting is a very rigid design to ensure longevity, stability, and offset the effects of temperature fluctuation.

The U and V axes are also extremely ways rigid. The ball screws and ways on the U and V axes of this machine are larger than those of the X and Y axes on some machines. It is a very solid “truss” design incorporated into the casting, not a small “taper box” suspended over the work area. The U and V axes also utilize direct-drive Panasonic AC servomotors.

The CHMER wire drive system and Auto Wire Threader – the best in the business CHMER unquestionably has the most reliable and fastest auto wire threader available. It consistently threads the wire through the kerf, submerged. While all other machines must reposition to the start hole to re-thread the wire, and then attempt to re-trace through the contour to the break point, the CHMER rethreads on location, through the kerf. The CHMER can consistently thread a .010 wire through a kerf approximately .013 wide. No other manufacturer even makes that claim. It also requires the least amount of maintenance. CHMER’s big secret is its absolute simplicity. Except for a small water-driven turbine wheel below the lower head, the CHMER wire threader has few moving parts apart from those used to transport the wire during normal cutting. This elimination of mechanical movement is the reason it is nearly maintenance-free, and the reason it can thread the wire in as little as ten seconds.

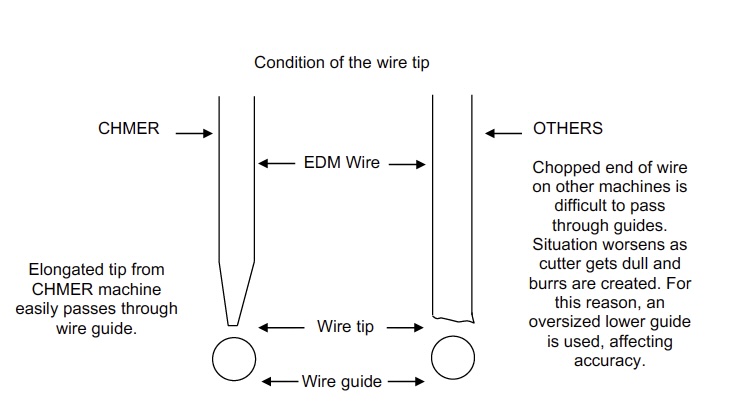

Most manufacturers use a powder brake or a friction clutch to apply wire tension during normal cutting. CHMER machines use an AC servomotor. This same motor is used to feed the wire during an auto wire thread operation. There is no water jet, no air jet, no tubes, no split guides, no AWT motor, no clutch, no depth stop to set. It all starts with the technique CHMER uses to sever the wire in the first place. The wire is heated and elongated until it is severed. Other manufacturers use a blade or other mechanical process to cut the wire.

Most manufacturers use a powder brake or a friction clutch to apply wire tension during normal cutting. CHMER machines use an AC servomotor. This same motor is used to feed the wire during an auto wire thread operation. There is no water jet, no air jet, no tubes, no split guides, no AWT motor, no clutch, no depth stop to set. It all starts with the technique CHMER uses to sever the wire in the first place. The wire is heated and elongated until it is severed. Other manufacturers use a blade or other mechanical process to cut the wire.

Precise wire drive system

Precise wire tension results in more accurate cuts, less wire breakage, and finer finishes. The two systems that contribute to CHMER’s superior wire drive system are, first, the servomotor application of tension, and second, the jockey roller. The servomotor is much more precise and smoother than a powder brake or friction clutch and can be controlled more accurately. The jockey roller eliminates changes in wire tension that are common in other machines by supplying the wire to the tensioner instead of dragging the wire through entire path. This is done by using another AC servomotor on the supply spool.

The result is that the wire tension measured anywhere before the tension motor is always the same, just a few grams.

Self-cleaning and self-lubricating tank seals

The CHMER tank seal design constantly flushes out the seals, whether the machine is submerged or not, and whether the machine is cutting or not. This counter premature wear of the seals, and since the water acts as a lubricant, it creates smoother motion, and a more accurate cut.

LCD Remote pendant control

Provided as standard equipment, the remote has an LCD position display and allows the operator to perform operations such as jog, center-find, edge find, AWT, program start, program stop, and more.

Auto lube system

The machine is equipped with an Auto Lube system that is pre-programmed to deliver the correct amount of lubricant at the correct intervals to all necessary parts of the machine.

Auto fluid level control

The machine automatically maintains the optimum water level inside the work tank based on the position of the upper head. The operator simply sets the position of the upper head (based on the workpiece thickness), and the machine does the rest.

Tank door interlock switch

CHMER’s decision to add a tank door interlock switch, at the cost of a few dollars, prevents a flood in the shop when (not if) someone sets up a cut and walks away without making sure the door is secured.

W5F CNC Control Overview of CNC Control features

- Extremely user friendly

- Auto cutting condition and cutter comp selection

- Automatic Corner Control

- Fast cutting– 24 in²/hr

- AC/DC Power Supply (Operator and machine selectable)

- Fine Finish Power Supply (OV)

- Very good PCD cutting characteristics.

- Six-axis capable

- Industrial-grade PC with dual Intel Pentium processors

- On-board help screen

- LAN port

- RS-232 Port

- USB Port

Details of CNC Control features

The CHMER W5F control uses normal G codes and is very easy to use. The geometry from almost any other Wire EDM can be used with virtually no editing. The W5F is also very fast, allowing instantaneous graphics representations on its 15” TFT display. There are 64 different coordinate systems, so zero points can be set for various fixtures or workpieces. It is simple to manage the power supply, too. Of course, power selections and offsets are chosen automatically by the control. Contour accuracy is enhanced through the automatic corner control feature. All parameters are easily edited. This is especially helpful when cutting exotic materials. For example, it is a simple matter to change from AC to DC power settings or select an alternate open voltage for a job. Although these features sound basic, they are not available on many other Wire EDMs. The W5F offers AC, DC, and OV Super Fine Finish capabilities.

There are many canned cycles built into the control such as edge find, center find, wire alignment, etc. which allow extremely fast setup. The W5F control can cut at speeds up to 24 in2 per hour (2” Thick with .010” Megacut D) and is six-axis capable (sixth axis option is available at additional cost). Several choices are offered for communicating with the control, such as Memory Cards, LAN port, RS-232, USB Port, and MDI. It is powered by an industrial-grade PC with dual Intel Pentium processors (motherboard and CPU) and 64Mb of DRAM. Error messages are quickly explained by simply selecting the Help screen.

Available options

- Submersible B Axis POR (Yukiwa, MMK & Ocean Available)

- Automatic Voltage Regulator $3,500.00

- Transformer for Voltages over 220 $1,750.00

- Wire Chopper $3,950.00

- 30 Kg. Spooler $5,000.00

- Two-piece Ruler Set with Clamps $3,150.00.

- BOBCAD V29 CAD-CAM software $1,795.00

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/

All product information including but not limited to price, specifications, color, photos, equipped with and features are subject to change.