Description

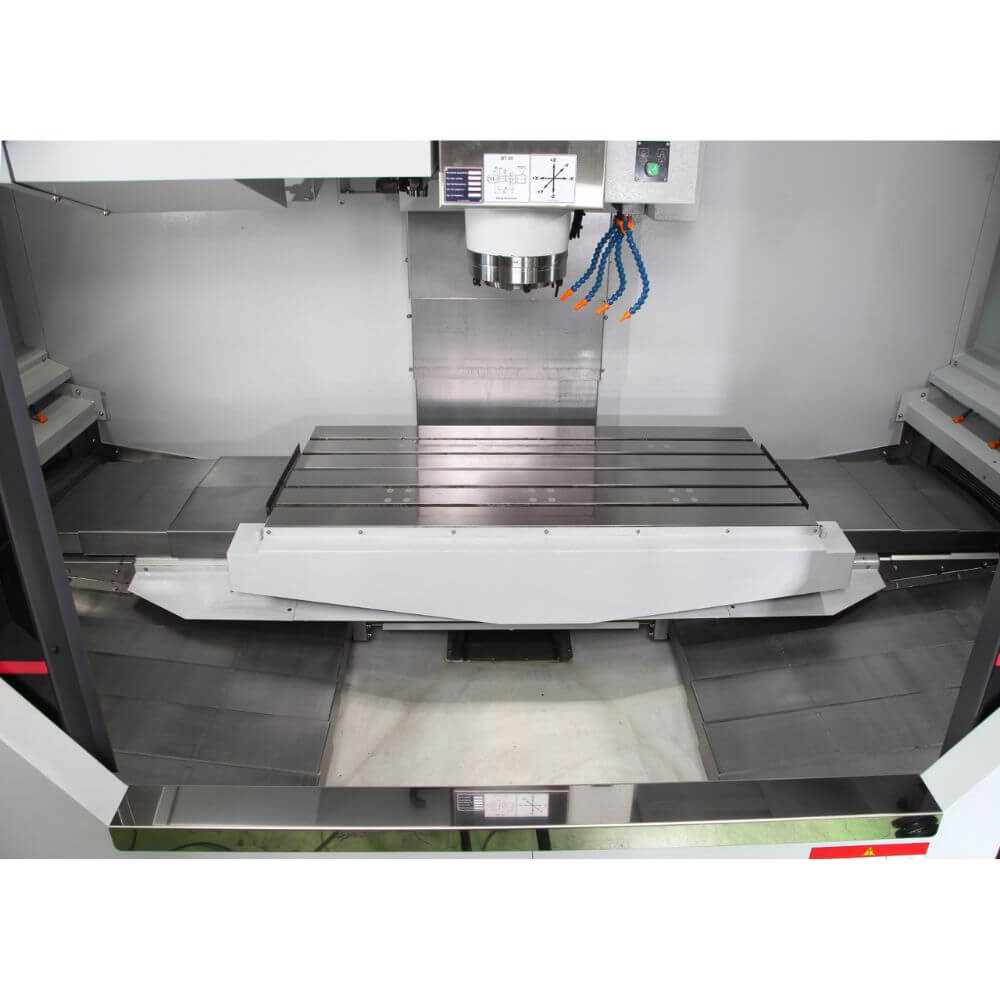

52″ x 25″ x 27″ New Hardinge Bridgeport XR Series Vertical Machining Center Model XR1320 Specifications:

| Travel | |

|---|---|

| X/Y/Z Axes | 51.96″ x 24.8″ x 26.77″ |

| Gage Line Height (Min-Max) | 5.9″ x 32.67″ |

| Y-Axis Throat Distance | 25.11″ |

| Table | |

| X Length | 55.11″ |

| Y Width | 23.62″ |

| Load Capacity | 2,200 lbs |

| T-Slots (# & Size) | 0.708″ x 3.94″ |

| Draw Bar | |

| Actuation | Pneumatic |

| Clamp Force | 900 kg |

| Clamp Method | Helical disk springs |

| Automatic Tool Changer (ATC) | |

| Taper (ISO No.) | 40 |

| Type | Swing Arm |

| Tool Holder Type | BT or CAT or ANDI or DIN (SK) |

| Pull Stud Type | 1. BT or modified BT for CAT 2. CT or modified CT for BT 3. ANDI or modified ANSI 4. DIN |

| Tool Selection | Random Bi-directional |

| Tool Capacity | 30/40 |

| Maximum Tool Diameter (Full Drum) | 75 mm |

| Maximum Tool Diameter (Ajd. Pockets Empty) | 150mm/130mm |

| Maximum Tool Length | 300mm |

| Maximum Tool Weight | 7 kg/8 kg |

| Tool Change Time (T-T) | 1.8 sec |

| Tool Change Time (C-C) ISO10791-9 | 7 sec |

| ATC Transmission | Cam |

| Axes Drives | |

| X axes servo motors | 3.0 KW (AIF12/4000, 12 Nm) |

| Y axes servo motors | 3.0 KW (AIF12/4000, 12 Nm) |

| Z axes servo motors with brake | 4.0 KW (AIF22B/3000, 22 Nm) |

| Continuous Thrust Rating X/Y axes | 4712N |

| Continuous Thrust Rating Z axis | 11519N |

| X, Y, Z-axis Acceleration | 4.7/4.2/4 (m/s2) |

| Ball Screws | |

| Ball Screw Size/Support | Fixed pre-tensioned |

| X-Axis | 45mm |

| Y-Axis | 40mm |

| Z-Axis | 45mm |

| Double Nut (Ball Nut) | STD |

| Lubrication | Automatic Central Lubrication |

| Ball Screw Pitch | X/Y: 16mm, Z: 12mm |

| Linear Guideway | |

| Type | Ball Guide |

| Way Size (X/Y/Z) | 35/45/45 |

| Linear Ways X-Axis | 2 |

| Linear Ways Y-Axis | 2 |

| Linear Ways Z-Axis | 2 |

| Linear Guide Trucks X-Axis | 6 |

| Linear Guide Trucks Y-Axis | 4 |

| Linear Guide Trucks Z-Axis | 6 |

| X, Y, and Z-Axis Rapid Traverse Rate | X/Y: 43m/min, Z 36m/min |

| Max. programmable feed rates (all axes) | 20m/min |

| Accuracy | |

| Positioning X | 0.015mm |

| Repeatability X | 0.009mm |

| Positioning Y, Z | 0.010mm |

| Repeatability Y, Z | 0.005mm |

| General Specifications | |

| Machine Weight | 8800kg |

| Machine Overall Width | 3300mm (Chip conveyor not included) |

| Machine Overall Height | 3165/2555 mm (Z at heighest/lowest) |

| Machine Overall Depth | 2265mm |

| Front Door Opening | 1400mm |

| Window Material | Laminated Panel (Lexan/Glass) |

| Coolant Tank Capacity (Liters) | 430L |

| Coolant Flow Rate for Cutter (L/min) | TPHK-4T 3-2, 130L/min, 1.5kg/cm2 (60HZ) / TPHK-4T 3-3, 130L/min, 1.25kg/cm2 (50HZ) |

| Coolant Flow Rate for Flush (L/min) (OPT) | TPHK-4T 6-6, 130L/min, 4.0kg/cm2 (60HZ) / TPHK-4T 7-7, 130L/min, 2.15kg/cm2 (50HZ) |

| Chip Removal | Chip conveyor |

| Air Requirements (PSI/SCFM) | 5.5 kg/cm2 minimum |

| Power Requirements | 220 volts 3 phase 60 hertz FLA 83 Amps |

Standard Features:

- Fanuc 0i-MF Plus 15″ Color LCD, Touch Screen Control with USB

- Coolant Chip Flush System

- 12,000 RPM Greased Direct Coupled Spindle with Chiller

- CT40 Spindle (BT opt)

- Dual Contact Big-Plus Spindle

- Hand-Held Manual Pulse Generator

- On board (2) SD Card Slots

- Fully Interlocked Machine Guarding

- Manual Chip Wash Gun

- 4th Axis Pre-wiring

- ECO Friendly Centralized Grease Lubrication

- Smart light LED with wireless

- Automatic X/Y/Z Axes Grease Lubrication

- Spindle Lubrication Oil Air

- Spindle Motor Stainless Deco

- Spindle Lateral Coolant Nozzles at Spindle Side

- One Year Machine Warranty Parts and Labor

- Three Year Control Warranty Parts and Labor

- Program and Data Protect Key

- Prep for 1000 PSI Through-Spindle Coolant (with rotary union)

- Automatic Power Off

- Retention Knobs

- Bright Dual Work Lights, and a Third Adjustable

- Inverter Drive ATC for Fast Recovery AIS System

- Renishaw OMP40-2+OMI-2T+OTS, Pre-Wiring Interface

- Cutter Air Blast

52″ x 25″ x 27″ New Hardinge Bridgeport XR Series Vertical Machining Center Model XR1320 Key Features:

Best Overall Working Cube in its Class

- 52 Inches in the X-Axis

- 24.8 Inches in the Y-Axis

- 26.7 Inches in the Z-Axis

Heavy Duty Linear Guideways, Ball Screws and Axis Drives

- To provide superior machine accuracy and repeatability the XR1320 comes complete with high-class 45mm double nut ballscrews on X & Z, and (2) 40mm ball screws on Y, fixed and pre-tensioned. Large 45mm high-quality linear guideways supported by 6 trucks on the X and Z Axis.

Powerful Spindle Motors

- Big Plus, 40 taper, 12,000-rpm Direct Drive spindle powered dual-wound spindle motor.

- 14.7/20/30hp (Cont./30 min/Peak)

- 55/75/110 ft-lbs Torque (Cont./30 min/Peak)

- Quad set of 70mm angular contact bearings and a 60mm rear taper roller bearing provide superior thermal stability, significant radial and axial stiffness and high accuracy.

- 1984 lbf tool retention for aggressive cutting applications.

Dual Y Axis Ballscrews

- Driven at the Center of Gravity Effect

- Improved Surface Quality

- Outstanding Acceleration

- Reduction of Vibration

- Improved Roundness

- Longer Tool Life

Fanuc OiMF-Plus Control Features

- 15″ LCD Color Display

- Programmable Data Input

- PCMCIA Card Slot

- Workpiece Coordinate System

- Manual Pulse Generator (Handwheel)

- Coordinate System Rotation

- Rigid Tapping

- Tool Life Management

- Tool Length compensation

- Background Editing

- Ethernet Ready / RS232 Ready / USB Slot

- Additional Workpiece Coordinate System

- Manual Guide i

52″ x 25″ x 27″ New Hardinge Bridgeport XR Series Vertical Machining Center Model XR1320 Optional Features:

- 40 Position 40 Taper Tool Magazine

- 12,000 RPM AIr/Oil Spindle, 30 HP DDS

- 15,000 RPM AIr/Oil Spindle, 30 HP DDS

- Absolute Linear Encoder

- Ball Screw Nut Cooling

- Through Spindle Coolant

- 4th Rotary Axes Interface

- Renishaw Probe Package OMI-2T + OMP- 40-2 + OTS

- ATC Auto Door

- Auto Central Grease System

- Spare M-Codes (8 Sets)

- Chiller for Power Case

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/

All product information including but not limited to price, specifications, color, photos, equipped with and features are subject to change.