Description

21″ x 23″ New Hardinge Slant Bed CNC Lathe Model Talent 51 (Standard Bed) Specifications:

| Main Spindle | |

| Collet Ready Spindle Config – ANSI | CFS/A2-6/20C |

| Draw Tube Type | Hydraulic |

| Through Draw Tube Capacity | 2″ |

| Gripping Capacity with Step Chuck & Closer | 8″ |

| Maximum Swing Over Way Cover | 21.65″ |

| 12-station max. turning diameter BMT45 | 11.41″ |

| 16-station max. turning diameter BMT45 | 9.44″ |

| Turning Length – max (without chuck) | 23.4″ |

| Turning Length – max (with chuck) | 18.35″ |

| Max. Speed (1 rpm Steps) | 5000 rpm |

| Base Speed | 1071 rpm |

| Continuous Power Rating | 14.75HP |

| Maximum Power Rating | 24.80HP |

| Continuous Torque Rating | 98.1 Nm |

| Maximum Torque Rating | 165 Nm |

| Sub-Spindle | |

| Collet Ready Spindle Configuration | A2-5/16C |

| Draw Tube Type | Hydraulic |

| Through Draw Tube Capacity | 1.65″ |

| Gripping Capacity with Step Chuck | 5.5″ |

| Max. Speed (1 rpm Steps) | 6000 rpm |

| Base Speed | 1500 rpm |

| Continuous Power Rating | 5HP |

| Maximum Power Rating | 15HP |

| Continuous Torque Rating | 23.5 Nm |

| Maximum Torque Rating | 70 Nm |

| Turret Configurations | |

| 12 Station with 1/2 Index Capability | BMT 45/DIN 1809 |

| Drive Configuration (opt. 16 Station) | BMT 45/DIN 1809 |

| Live Tooling Drive System | |

| Max. Speed (1 rpm Steps) | 5000 rpm |

| Maximum Power Rating | 5HP |

| Maximum Torque Rating | 26.1 Nm |

| Travels and Feed Rates | |

| X Axis Travel Max – Live Tooling (BMT) | 7.08″ |

| Z Axis Travel Max | 25.67″ |

| Y Axis Travel Max | 1.65″ |

| X and Z Axis Rapid Traverse Rates | 1181 ipm |

| Y Axis Rapid Traverse Rates | 394 ipm |

| Machine Accuracy | |

| Evaluation Standard | ISO 230-2 |

| Repeatability – X & Z Axes (ISO) | 0.000197″ |

| Machine Dimensions | |

| Length | 114.7″ |

| Depth | 72.2″ |

| Height | 76.1″ |

| Weight | 12,786 lbs |

| Power Requirements volts/amp/phase | 220V/67 FLA/3 phase |

| Air Requirements | 70-90 PSI |

Standard Features:

- A2-5 16C collet-ready spindle

- BMT 45 live tooling 12-station with 1/2 index capability

- Central grease lubrication (manual)

- Foot switch main spindle chuck/collet-open/close

- Foot switch sub-spindle chuck/collet-open/close

- Headwall coolant (main & sub-spindle)

- Bar feed interface

- Chip conveyor interface

21″ x 23″ New Hardinge Slant Bed CNC Lathe Model Talent 51 (Standard Bed) Key Features:

- Collect-Ready Main Spindle: The Hardinge collet-ready spindle is the most versatile machine spindle in the industry – it is uniquely designed to accept both collets and jaw chucks without the use of an adaptor. Because the collet seats directly in the spindle, the workpiece is held close to the spindle bearings which provides the ultimate in accuracy, rigidity and gripping force. It also allows for maximum spindle RPMs which increases productivity. This exclusive design also offers numerous workholding capabilities including solid collets, master collets, dead length collets, step chucks, 3-jaw chucks and FlexC collets systems.

- Collet-Ready Sub-Spindle: The belt driven sub spindle features a 15Hp (11.5Kw) motor with a speed range of up to 6,000RPM. The A2-5/16C collet-ready spindle allows for the use of a complete assortment of spindle tooling including collets and jaw chucks. It also includes a hydraulic collet-closer and rigid tapping is standard. Please note that step chucks are not compatible on sub-spindle.

- Hardinge CFS Spindle: The spindle design is both collet and jaw chuck-ready and does not require a spindle adaptor. Hardinge C Style collets seat directly into the spindle closest to the bearings, so that spindle accuracy is transferred directly to the workpiece. Take advantage of using maximum spindle speeds and feeds, utilizing the maximum working envelope with quick job to job changeover from bar work to chucking, allowing for higher part to part accuracy, better surface finish with longer tool life capability.

- Collet-Ready Spindle Advantages

- Collet seats directly in the Hardinge spindle

- Maximum rigidity and gripping power is transferred to the part

- Maximum utilization of RPM

- Minimum weight on spindle

- Minimum overhang from the spindle bearings that assures spindle accuracy is transferred directly to the workpiece

- Optimum T.I.R.

- Gripping force directly over the workpiece

- Superior tolerances and finishes

- Capable of using maximum machine stroke capacity

- Longer tool life

- Quick changeover

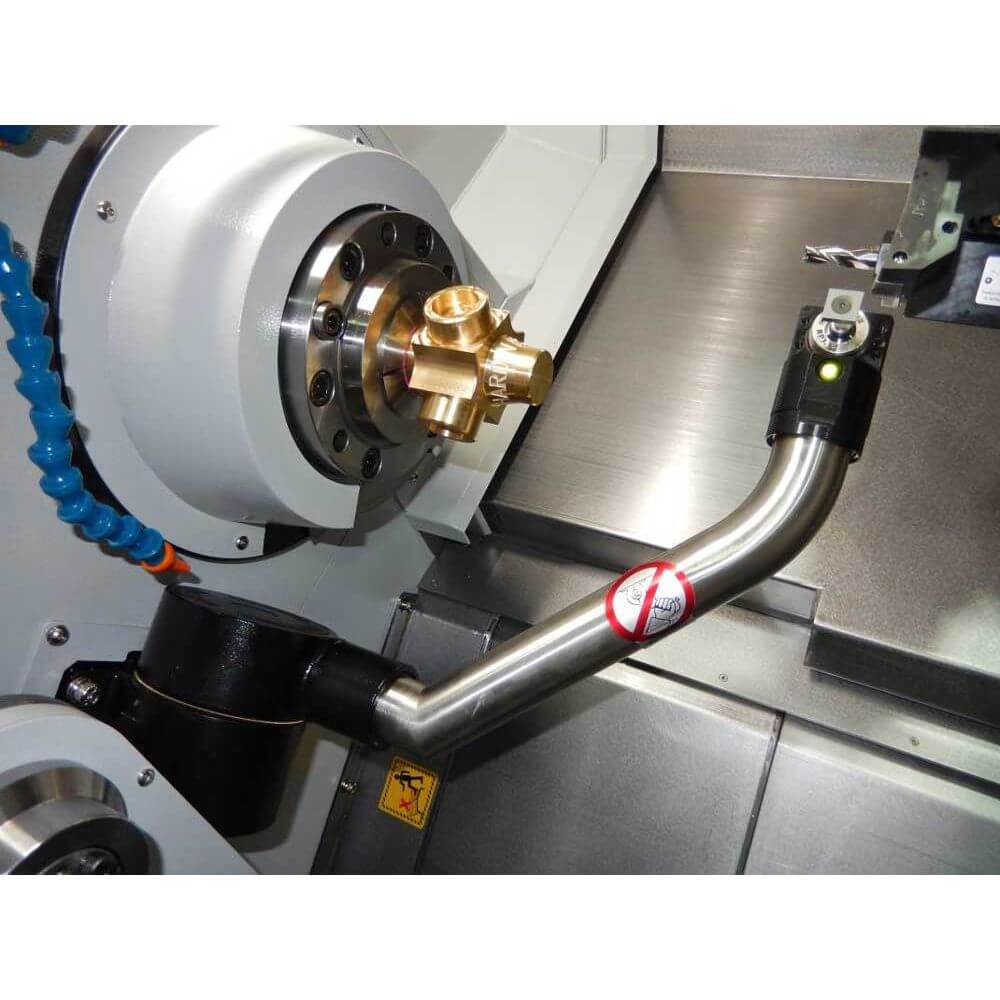

- Live Tooling: Live tool holders start at 5,000 RPM and are capable of up to 20,000 RPM when purchased with ratios of 2:1 or 4:1 when high speeds are required. The Hardinge BMT live tooling holders provide superior run-out within .00012” (3 micron) making it the overall best in class tooling system.

Machine Construction:

- Y-Axis: Y-axis capability is a huge productivity enhancement on a turn/mill machine tool. To get Y-axis motion, an extra set of ways is used to move the live tool across the face of the spindle. By adding a third linear axis to the turning-center turret it enables rotary cutters to machine across the spindle center line thus greatly expanding the milling capabilities of the machine.

- Tailstock: The servo driven tailstock features a non quill style body and is fully programmable with torque control to set the tailstock force, as well as advance or retract between machining cycles. Multiple positioning is possible to allow for multiple bar feed out applications. The system will accommodate either a live or dead center with a #4 Morse taper.

- Machine Base: The latest software design platform and FEA (Finite Element Analysis) techniques were used to design and build a rigid, structurally-balanced machine to assure optimum performance and machine life. The FEA software accurately depicts the structural deflection, stress levels, thermal response and vibration response of the assembled components and the assembled machine. Extreme-case loadings are used to verify adverse machining conditions.

21″ x 23″ New Hardinge Slant Bed CNC Lathe Model Talent 51 (Standard Bed) Fanuc 31i TB Controls:

- Programming Functions

- Absolute/Incremental Programming

- Additional Custom Macro Variables

- Alarm Display

- Auto Acceleration/Deceleration

- Auto Coordinate System Setting

- Background Editing

- Canned Cycles (Drilling)

- Chamfer/Corner Rounding

- Circular Interpolation by R Programming

- Constant Surface Speed Programming

- Continuous Thread Cutting

- Coordinate System Setting (G50)

- Custom Macro B

- Decimal Point Programming

- Diameter/Radius Programming

- Direct Drawing Dimension Programming

- Display Position, Program, Alarm, History

- Extended Part Program Edit (copy/replace)

- External Workpiece Number Search

- Hardinge Safe Start Format

- Helical Interpolation (for Y-Axis)

- Helical Interpolation (for Non Y-Axis)

- Help Screen

- Input of Offset Values by (G10)

- Interpolation (Linear/Circular)

- MPG Manual Pulse Generator

- Manual Guide i with full color display

- Multiple Repetitive Cycles I (Turning)

- Multiple Repetitive Cycles II (Pocketing)

- Multi Spindle Control

- Program Number Search

- Programmable Parameter Input

- Reference Point Return

- Registered Part Program Storage (1000)

- Rigid Tapping

- Spindle Orient Main & Sub (Std. on Live Tooling Models)

- Spindle Synchronization (Main & Sub)

- Sequence Number Search

- Single Block Operation

- Skip Function G31

- Stored Stroke Check 1, 2 & 3

- Sub Program Call (10 fold nested)

- Thread Cutting Retract

- Thread Cutting

- Tool Life Management

- Tool Nose Radius Compensation (Geometry/Wear)

- Variable Lead Thread Cutting

- Workpiece Coordinate System (G52-G59)

- General

- Pendent-mounted Full Control

- 10.4” LCD Display

- Graphic Display

- Embedded Ethernet

- RS-232C Communication Ports

- PCMCIA and USB Ports

- Program Resolution .0001” (.001mm)

- Tool Offset Capability .0001” (.001mm)

- Tool Offsets with Geometry/Wear (99)

- Absolute Encoders

- Inch/Metric Selection by G-Code

- Part Program Storage 2MB

- Miscellaneous

- Actual Cutting Speed and T-Code Display

- Dual Check Safety

- English

- French/German/Italian/Spanish Language

- Chinese in FANUC menus only

- Full Keyboard

- Ladder Diagram Display

- Polar Coordinate Interpolation

- Cylindrical Interpolation

21″ x 23″ New Hardinge Slant Bed CNC Lathe Model Talent 51 (Standard Bed) Machine Flexible Workholding Options:

- Collets: Hardinge hardened and ground collets are inspected and measured in a Hardinge SUPER-PRECISION® spindle. Collets are available in fractional round, hex and square sizes and round metric, as well as round serrated fractional and metric sizes. Use adjustable, machinable collet stops for accurate part positioning

- Emergency Collets: Emergency collets have a soft face with a pilot hole for customer drilling, boring and stepping out to the exact size required. An optional extended nose permits deeper counterbores when required and tool clearance for extended work.

- FlexC™ Quick-Change Vulcanized Collet Systems: Interchangeable quick-change vulcanized collet heads have a working range of ±.020″ (0.5mm) to accept bar stock variation. Collets change in seconds, while accuracy is maintained at .0004″ (.010mm).

- Style “S” Master Collets and Pads: Pads can be changed much quicker than solid collets can. Pads cost less and use less storage space when compared to a standard solid collet. Choose from hardened and ground, semi-hard and emergency pads. Styles S16, S20 and S26 require a collet closer.

- Jaw Power Chucks: Hardinge power chucks are lever operated, counter-centrifugal and dynamically balanced. Quick-change chucks are also available.

- Sure-Grip® Expanding Collet Systems The Hardinge Sure-Grip expanding collet provides high-precision, internal gripping solutions with true parallel gripping. Collet-style and spindle-mount styles are available, depending on the machine model. Master Expanding Collets are a lower-cost alternative to SureGrip Expanding Collet Systems and include a dead-length feature.

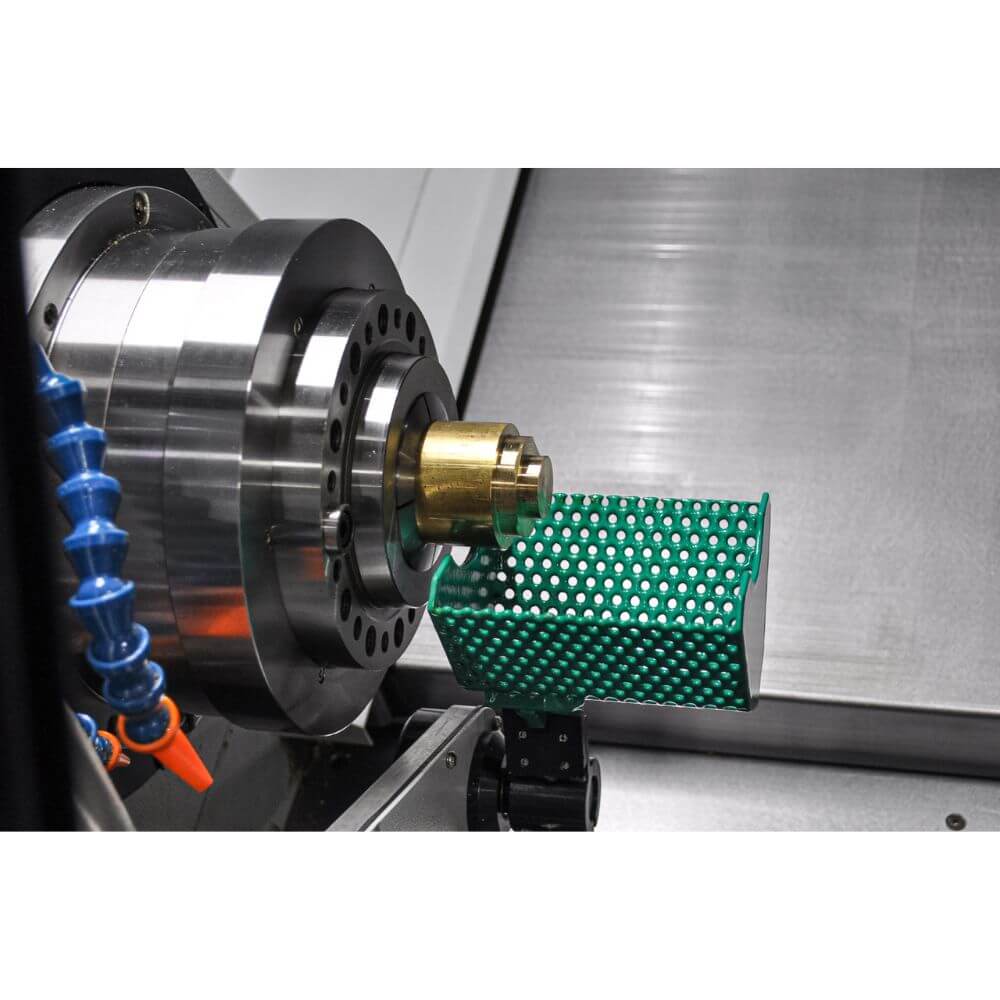

- Step Chucks and Closers* Step Chucks and closers are used to accurately hold larger diameter parts. * Main spindle only

- Force-Limiting Step Chuck The Hardinge force-limiting step chuck has built-in force control to safely grip thin-wall parts. Maintain inside and outside concentricity in a fail-safe process while eliminating the nuisance of manually tweaking the draw bar.

- Dead-Length® Systems Maintain part-length control by using Hardinge dead-length systems. Choose from dead-length collet assemblies, thru-hole collets, step chucks and spider-stop step chucks. 16C to #22 B&S adapter shown on A2-5 sub-spindle.

Machine Options:

- Central grease lubrication (auto pump lubrication)

- Coolant & air management systems

- Coolant through main & sub-spindle

- Pressure coolant with max. 1000 PSI

- Mist collector unit

- Headwall airblast main & sub-spindle

- Power transformer

- Auto door

- Measurement systems

- Tool touch probe – Renishaw

- Component part probe – Renishaw

- Chip management systems

- Right side hinge type chip conveyor

- Right side scraper type chip conveyor

- Component part handling

- Parts catcher – main spindle to trap-door

- Parts catcher – main spindle with parts conveyor

- Sub-spindle part detection

- Sub-spindle part ejection

- Live center, #4 morse taper for tailstock

- 8 sets of spare M codes

- BMT 45 16-station live tooling turret (no half index capability)

- BMT 45 statics tooling package

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/

All product information including but not limited to price, specifications, color, photos, equipped with and features are subject to change.