Description

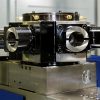

26″ x 160″ Kingston CNC Lathe Model CL38A 4.7″ Bore for sale

Kingston’s versatile CL38 model is designed for universal workpieces in a variety of industries, including energy, mining, textile, paper, and transportation. The CL38 features 26” swing, a choice of 4.7” or 7.3” bore, and lengths from 40” – 160″. It is equipped with a powerful 30 HP spindle motor, a sub-spindle tailstock ready to mount a chuck, and both V8 and H6 servo turrets — with a maximum cutting diameter of 14.5″ between turrets. This flexibility and ease of use make the CL-38 one of our most popular CNC models.

26″ x 160″ Kingston CNC Lathe Model CL38A 4.7″ Bore Specifications:

| Capacity | |

| Swing Over Bed | 26″ |

| Maximum Cutting Diameter (2 Turrets) | 14.5″ |

| Distance Between Centers | 172″ |

| Maximum Cutting Length | 157″ |

| Width of Bed | 18″ |

| Headstock | |

| Spindle Bore | 4.7″ |

| Spindle Motor | 25/30 HP (30 min.) |

| Type of Spindle Nose | A2-11 |

| Gear Box | |

| Number of Speed Ranges | 2 |

| Spindle Speed (RPM) | 6-1600 |

| Turret | |

| Turret | V8 Hydraulic & H6 Servo |

| Traverse | |

| Max. Stroke | X-Axis: 21.2″ Z-Axis: 164.2″ |

| Rapid Traverse | X-Axis: 394 in/min Z-Axis: 394 in/min |

| Motor | |

| Servo Motor | X-Axis: 3.6 HP Z-Axis: 5.4HP |

| Ball Screw | |

| Ball Screw | X-Axis: Ø1.41”, P6 Z-Axis: Ø1.97”, P8 (80″), P12 (120″), P16 (160″) |

| Tailstock | |

| Tailstock Quill Center | M.T. # 5 |

| Tailstock Quill Diameter | Ø5.9” |

| Tailstock Quill Travel | 8.6” |

| Machine Height | 79″ |

| Dimensions | |

| Floor Space (LxW) | W: 91″ L: 329″ |

| Weight | |

| Net Weight (lbs) | 22,220 |

| Total Power Required | 35 KVA |

Price and specifications subject to change without notice.

The machine will be guaranteed free from defective material and workmanship for a period of one (1) year under normal working conditions on a one–shift basis (8 hrs. daily), excluding misuse by customer.

Electrics guaranteed for a period of one (1) year (parts only).

Standard Equipment & Accessories:

- 25/30 HP (30 min) Fanuc aP40i AC Spindle Motor, 220V (only), 3 Phase, 60 Cycle

- Fanuc 0iTF-Plus Controller with Manual Guide i & Threading Repair, 10.4″ LCD Monitor

- Front Chuck Ready Spindle

- Rear Spindle Adapter (7.3″ Bore Only)

- Rear Spindle Safety Door

- V8 (Front) & H6 (Rear) or H4 Servo Turret

- 9.25″ Steady Rest w/Roller Jaw (Min. 1.57″)

- Tailstock with Sub-Spindle Function and Chuck Mounting Capability

- Water Spray Gun for chip Cleanup

- Tailstock Movable by Engaging with Carriage

- Dead Center for Tailstock MT#5

- Coolant System w/6 Bar Pressure

- Auto Lubrication System

- Two Doors and Full-Length Back Splash Guard

- Rear Chip Conveyor

- Halogen Light

- Foundation Pads, Leveling Screws

- Tool Box and Tools

- Operation, Electric, Controller & Parts Manual

STANDARD TOOLING PACKAGE

| Turret | V8 | H6 | H4 (Opt.) | ||||

| Tool Center Height | 1″ | 1-1/4″ | 1-1/4″ | ||||

| Wedge Block | 8 pcs | 8 pcs | 8 pcs | ||||

| Facing Tool Holder | 1″ | 2pcs | |||||

| Boring Bar Holder | 1-1/2″ | 4 pcs | 2″ | 6 pcs | 2′ | 4 pcs | |

| Boring Bar Sleeve | 1-1/4″ | 2 pcs | 1-1/2″ | 2 pcs | 1-1/2″ | 2 pcs | |

| 1″ | 2 pcs | 1-1/4″ | 2 pcs | 1-1/4″ | 2 pcs | ||

| 3/4″ | 2 pcs | 1″ | 2 pcs | 1″ | 2 pcs | ||

| 5/8″ | 2 pcs | 3/4″ | 2 pcs | 3/4″ | 2 pcs | ||

| 1/2″ | 2 pcs | ||||||

| 3/8″ | 2 pcs | ||||||

| Drilling Sleeve MT#3 | 2″ | 1 pc | 2″ | 1 pc | 2″ | 1 pc | |

| Drilling Sleeve MT#4 | 2″ | 1 pc | 2″ | 1 pc | 2″ | 1 pc | |

Note: No credit allowed for deletion of individual tool sleeves in the standard tooling package.

Optional Accessories:

- Additional 9.25″ Steady Rest w/Roller Jaws (Min. Capacity 1.57″). $3,300

- 15.9″ Steady Rest w/Roller Jaws (Min. Capacity 7.48″). $3,600

- Follow Rest (1.57″-4.75″). $4,000

- 2.5″ Boring Bar Support. $2,700

- Fanuc Arbitrary Speed Threading + Thread Lead Teach: Spindle FWD $2,500

- Fanuc Arbitrary Speed Threading + Thread Lead Teach: Spindle FWD + REV $3,000

- A2-11 Rear Chuck Adapter for CL38A (4.7″ Bore). $1,000

- Headstock Cooling Unit. $2,800

- Transformer 480V to 220V $2,700

- Full Enclosure. Upon Request

- Without Tailstock (Factory Removal Only). Upon Request

Turret Options:

Saulter BMT-55 V12 Live Tooling Turret + 2.5° C-Axis Spindle Indexing. Upon Request

Tool Holders for V8, H4, & H6. Upon Request

H4 Servo Turret Instead of H6 (Factory Installation Only) No Charge

Without Front or Rear Turret (Factory Removal Only). Less $5,000

Replace Rear H6 Turret with Tool Block + T-Slot Less $3,000

Workholding

- 18″ 3-Jaw Hydraulic Chuck + System (4.3″ bar capacity, A2-11). $20,000

- 18″ 3-Jaw Hydraulic Chuck + System (6.5″ bar capacity, A2-15) $31,200

- Taiwan KC 18″ 4-Jaw Ind. Chuck (6.2″ hole, solid jaws, semi-steel body, A2-11) $3,000

- Taiwan KC 20″ 4-Jaw Ind. Chuck (6.2″ hole, solid jaws, semi-steel body, A2-11) $3,700

- Taiwan KC 22″ 4-Jaw Ind. Chuck (8.1″ hole, solid jaws, semi-steel body, A2-15) $4,800

- Taiwan SK 20″ 3-Jaw Scroll Chuck (8.1″ hole, solid jaws, semi-steel body, A2-15). $8,700

- Bison 20″ 4-Jaw XHD Ind. Chuck (6.6″/8.1″ hole, 2 pc jaws, forged steel). $9,250

- Bison 20″ 3-Jaw XHD Scroll Chuck (7.5″/8.0″ hole, 2 pc jaws, forged steel). $13,900

- Other Hydraulic, Air & Manual Chucks. Upon Request

Kingston CNC Lathe Video

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/