Description

40″ x 80″ Kingston SPX 40 Heavy Duty CNC Lathe 14.7″ Bore

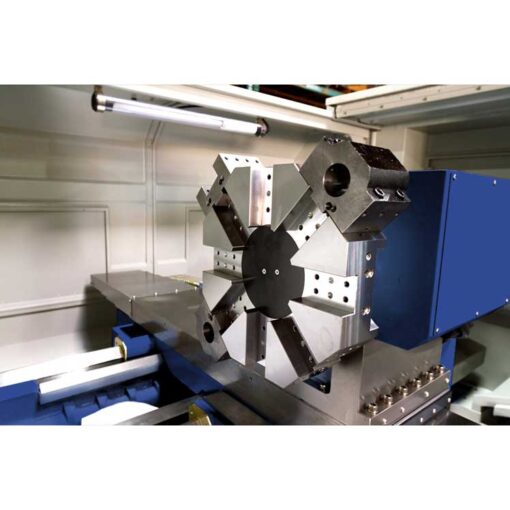

The SPX-40 is Kingston’s newest and beefiest entry in its large-format slant bed line. With 40.5″ swing over bed (35.4″ max turning), bed lengths to 280″, and available bore sizes up to 14.7″, the SPX-40 is a powerful – yet versatile – beast that delivers under the heaviest loading and cutting conditions. Optional C-Axis and Y-Axis capability combined with the APT 60 V12 Live Tooling Turret puts the SPX-40 in a league of its own in terms of large-swing and big-bore milling and drilling operations on a slant bed lathe. Our 12-position servo turret is specially designed with a 2-piece large diameter Hirth-type coupling for strong clamping force and high-loading capacity while delivering precise positioning. Each SPX is run by Fanuc’s reliable 0iTF-Plus controller.

40″ x 80″ Kingston SPX 40 Heavy Duty CNC Lathe 14.7″ Bore Specifications:

| Capacity | |

| Swing Over Bed | 40.5″ |

| Swing Over Saddle | 37.4″ |

| Max Cutting Diameter | 35.4″ |

| Max Turning Length | |

| 8.0″ Bore | 74.8″ |

| 9.25″ Bore | 74.8″ |

| 10.1″ Bore | 72.8″ |

| 12.5″ Bore | 61.0″ |

| 14.7″ Bore | 61.0″ |

| Bed | |

| Slant Bed Angle | 45″ |

| Guide Way | Box Way |

| Headstock | |

| Spindle Bore | 9.25″ |

| Spindle Nose | A2-15 |

| Spindle Speed (2 Step Gear) | 850 RPM |

| Spindle Motor | 40 / 50 HP (30 min) |

| Travels | |

| X-Axis | 17.7″ + 0.7″, 16.5 + 1.1 (200″ C.C. only) |

| Z-Axis | 82.6″ |

| Rapid Traverse – X Axis (ipm) | 787″ |

| Rapid Traverse – Z Axis (ipm) | 629″ |

| Turret | |

| Tooling System | BOT |

| Indexing Time: Next Tool | 0.6 sec |

| Number of Tools | 12 Station |

| Square Tool Size | 1.25″ |

| Round Tool Shank Size | 3″ |

| Tailstock | |

| Quill Taper | MT#6 |

| Quill Stroke | 5.9″ |

| Quill Diameter | 6.29″ |

| Dimensions | |

| Floor Space Required W x L | 109″ x 271″ |

| Height | 118″ |

| Weight (lbs) | 40774 |

| Power Required | 65 KVA |

Price and specifications subject to change without notice.

The machine will be guaranteed free from defective material and workmanship for a period of one (1) year under normal working conditions on a one-shift basis (8 hrs. daily), excluding misuse by customer.

Electrics guaranteed for a period of one (1) year (parts only).

Standard Equipment:

- 40 HP / 50 HP (30 min) AC Spindle Motor (Fanuc), 220V, 3 Phase 60 Cycle

- 15″ 3-Jaw Hydraulic Cylinder & Chuck (5.1″ bore only) w/3 Sets Soft Jaws & 1 Set Hard Jaws

- FANUC 0iTF-Plus Controller w/Manual Guide i,10.4″ LCD Monitor, Ethernet connection

- Registered Part Program Number: 400 Sets

- Part Program Memory Size: 512kb

- V12 Servo Turret

- Programmable Tailstock Body & Quill

- Fully-Enclosed Z Axis Way Cover

- Chain Type Chip Conveyor + Chip Cart

- Coolant System (4-Bar)

- Heat Exchange for Electric Cabinet

- Lubrication System

- Hydraulic Power Supply Unit

- Three-Color Warning Lights

- Work Light

- Safety Interlock on Door

- Tool Box & Tools

- Operating, Maintenance, Controller & Parts Manual

Standard Tooling Package:

| Turret | V12 | |

| Tool Center Height | 1-1/4″ | |

| Facing Tool Holder (R/H) | 1-1/4″ x 1-1/4″ | 1 pc |

| Facing Tool Holder (L/H) | 1-1/4″ x 1-1/4″ | 1 pc |

| Boring Bar Holder | 3″ | 2 pcs |

| 2″ Boring Bar Socket | 5/8″ | 1 pc |

| 3/4″ | 1 pc | |

| 1″ | 1 pc | |

| 1-1/4″ | 1 pc | |

| 1-1/2″ | 1 pc | |

| U-Drill Holder | 2″ | 1 pc |

Optional Accessories:

- C-Axis Controller Upgrade + APT 60 Live Tooling Turret POR

- Y-Axis + C-Axis w/Controller Upgrade + APT 60 Live Tooling Turret. POR

- 50/60 HP Motor Upgrade. POR

- 0 Degree Rotary Tool Holder. $4,000

- 90 Degree Rotary Tool Holder. $8,000

- Renishaw HPRA Tool Setter. $5,600

- Renishaw HPRA Tool Setter. $4,800

- Fanuc Arbitrary Speed Threading $2,500

- Oil Mist Collector. $2,400

- Oil Coolant Skimmer. $800

- Air Cooler for Electrical Cabinet. $1,300

- Upgrade to 20-Bar Coolant System. POR

- Upgrade to 70-Bar Coolant System. POR

- Transformer. $3,200

- 24″ 3-Jaw Hydraulic Chuck, Cylinder and System (1400 RPM). $29,500

- 32″ 3-Jaw Hydraulic Chuck, Cylinder and System (800 RPM, 9.05 Bar). $44,500

- Hydraulic Steady Rest SMW SLU4 (Ø1.38″ – 9.65″). $36,500

- Hydraulic Steady Rest SMW SLU-B-Z 5 (Ø1.97″ – 12.20″) $63,900

- Hydraulic Steady Rest SMW SLUB-B-Z 5.1 (Ø3.54″ – 13.78″). $71,500

- Hydraulic Steady Rest SMW SLU-K 5.1 (Ø3.94″ – 16.14″). $63,900

About Us

Worldwide Machine Tool is the leader in providing full sales, parts and service, financing, transportation and training of new and used machine tools for chip and fabrication clients across the United States, Canada and Mexico. Our warehouses and office is located just minutes north of Columbus, Ohio. With over 28 years of experience in the industrial machine tool industry, we have the knowledge and expertise to provide our customers with the best customer service, support and technical expertise on all new and used machine tools to meet their needs.

We buy and sell new and used ironworkers, shears, lathes, milling machines, drills, saws, press brakes, routers, turret punch models, presses, welders, deburring and beveling machines, plate rolls, laser, waterjets and associated tooling and accessories. We take pride in being a trustworthy partner that our customers rely on through the years. Our experienced sales team would love to help you with your next machine tool purchase. Give us a call today or Request A Quote. Call 614-255-9000 or Contact us today to experience the Worldwide Machine Tool difference.

Check us out on Twitter, Facebook, Youtube, and Instagram.

Worldwide Machine Tool LLC.

Terms and Conditions: https://www.worldwidemachinetool.com/terms-conditions/